The Group Stellantis continues to diversify its technology portfolio. After the apparent shift towards lithium-iron-phosphate (LFP) batteries and investment in solid-state batteries, the group today announces a new partnership with Zeta Energy to develop lithium-sulfur batteriesa more economical technology.

A new bet on lithium-sulfur batteries

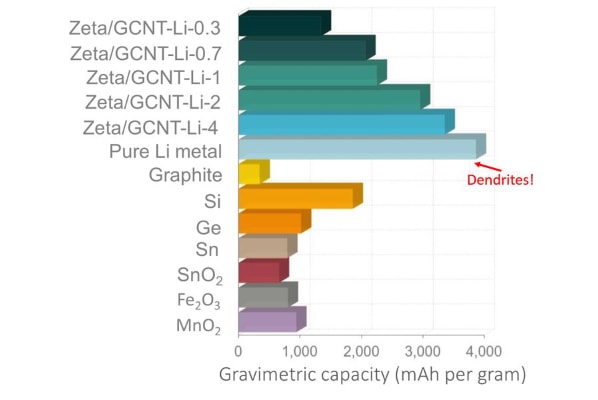

According to the press release from Stellantis and Zeta Energy, lithium-sulfur batteries offer many advantages compared with conventional lithium-ion batteries. Not only are they lighter, they are also more environmentally friendly thanks to the use of recycled materials and unrefined sulfur, an industrial by-product. The technology also promises high energy density, making it possible toincrease the range of electric vehicles while reducing their weight. Added to this is a significant cost reduction, lithium-sulfur batteries are advertised at less than half the price of lithium-ion batteries per kilowatt-hour.

The agreement between Stellantis and Zeta Energy includes the joint development of a battery pack optimized for fast recharging, up to 50 % faster than current technologies.

Economic and environmental benefits

Lithium-sulfur technology stands out for its low production costs, thanks in large part to the absence of rare metals such as cobalt, nickel, manganese or graphite. By relying on a short, local supply chain, the lithium sulphur battery approach not only reduces logistics costs, but also reduces dependence on the countries from which rare metals are sourced.

At the same time, lithium-sulfur batteries promise to significantly reduce CO2 emissions during manufacturingThis is made possible by the use of recycled methane and sustainable materials.

Stellantis advances in China and the United States, slows down in Europe

This partnership with Zeta Energy enhances Stellantis' already diversified technological ecosystem. In 2023, the group signed a partnership with CATL to integrate LFP batteries in models such as the Citroën e-C3 and the electric Fiat Grande Panda. These batteries, popular in China for their durability and competitive cost, enable Stellantis to offer more affordable electric vehicles for the entry-level segments.

At the same time, Stellantis strengthens collaboration with Factorial Inc.. for developing solid-state batteriesa technology designed for high-end and sporty vehicles. These batteries, which are due to be tested in vehicles such as the Dodge Charger Daytona as early as 2026, offer interesting performance features: extended range, reduced weight, and easy integration into existing production lines.

In both cases, Zeta Energy and Factorial Inc. are American companies, demonstrating, once again, how Europe is lagging behind on this issue, and more specifically on the ACC gigafactory.a joint venture between Stellantis, Mercedes-Benz and TotalEnergies, of which the Termoli (Italy) and Kaiserslautern (Germany) projects are on hold. Add to this the news of the Northvolt gigafactory in Germany, currently in bankruptcy...

In the end, Stellantis adopts a pragmatic "double chemistry" approach to meet the needs of all its customers. On the one hand, LFP and lithium-sulfur batteries aim to reduce costs and make electric vehicles more accessible, as Citroën and Fiat have done. On the other, solid-state batteries target the high-end with superior performanceideal for brands like Alfa Romeo and Maserati.

For the moment, we're a long way from series production.

The idea is not to close ourselves off from the technological matrices that will enable us to improve EV batteries.

If Li-S were to become established in the near future, Europe would benefit.

Saft, a French subsidiary of Totalenergies, is also working on this Li-S battery solution. Totalenergies is also associated with Psa/Stellantis and Daimler BEnz within ACC...

Can't agree more.