It's a masterpiece in 33 acts. A rolling work of art shaped by technological innovation and craftsmanship. The news Alfa Romeo 33 Stradaleproduced in just 33 units, reveals its secrets through a unique immersion between Balocco, Arese and Turin. Here's a behind-the-scenes look at the most exclusive supercar ever designed by the Italian marque.

Balocco: raw emotion on the track

First stop on this journey of initiation: the legendary Balocco test track. It's here, on this historic playground of racing cars Alfa Romeoguests were able to test the "00" prototype of the 33 Stradale. Read the test here: I drove the Alfa Romeo 33 Stradale supercar.

The result is a car that combines visceral sensations with surgical balance. The mid-mounted, twin-turbocharged 630 hp V6 propels the car to 333 km/h. Two driving modes are available: "Strada" for the open road, "Pista" for extreme driving. Braking? From 100 to 0 km/h in less than 33 meters, thanks to Brembo carbon-ceramic brakes.

La Bottega Alfa Romeo: the luxury of made-to-measure cars

The 33 Stradale can't be ordered, it has to be created. This unique approach comes to life in the "Bottega Alfa Romeo", an intimate and symbolic space within the Arese museum. It is here, in the same room where the original 33 was born in 1966, that customers are received as patrons, invited to shape their own work.

This co-creation process is inspired by the workshops of Renaissance craftsmen: here, the raw materials are not wood or stone, but aluminum, carbon, leather, Alcantara, and an infinite palette of shades. Each customer works closely with designers, engineers and even brand historians, to make the 33 Stradale not only unique, but also consistent with the Alfa Romeo spirit.

Using high-precision 3D simulators and exposed materials, they can see, touch and adjust every detail. The slightest wish is submitted to the "Comité 33" for approval, followed by technical validation. This approach, which is as rigorous as it is passionate, appealed to us right from the start: All 33 copies sold out within weeks of the first drawings being presented, in 2022 at the Monza Grand Prix.

Touring Superleggera: handcrafted production

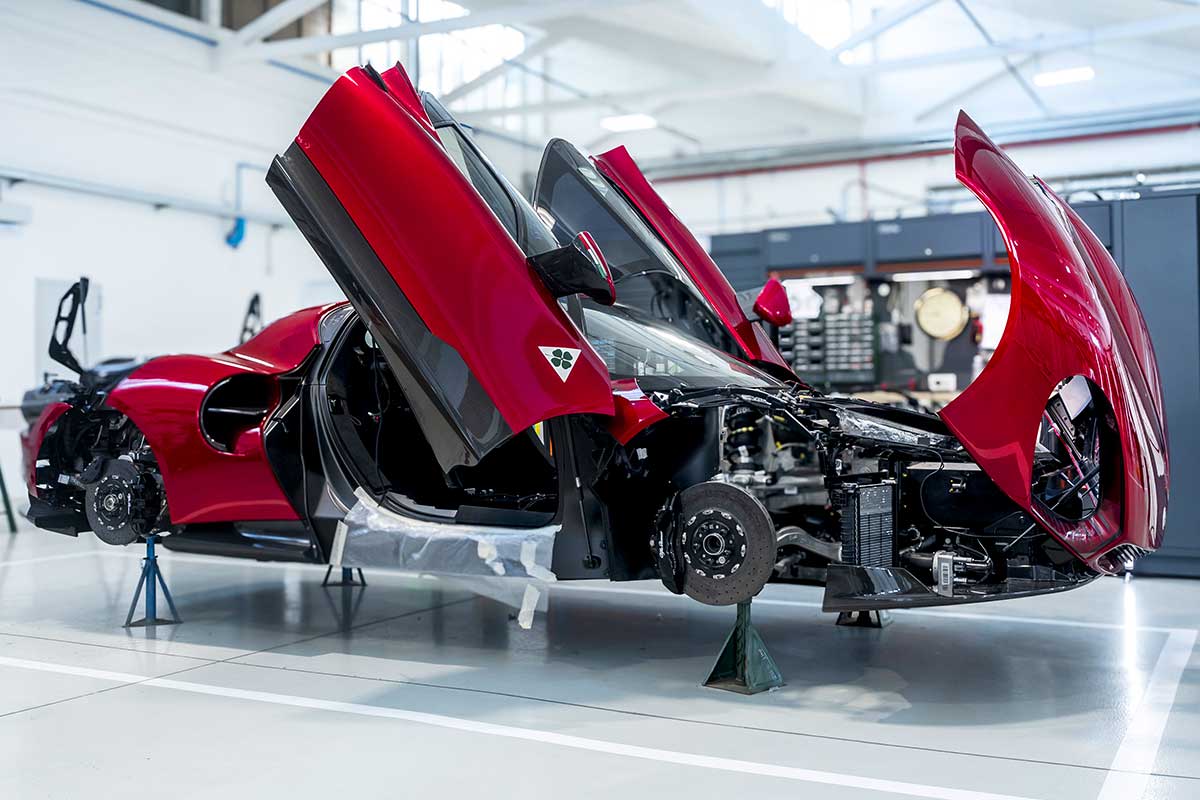

It's in the workshops of Carrozzeria Touring Superleggera, in Turin, that the magic takes shape. Since 1926, this exceptional coachbuilder has combined tradition and precision to bring rare automobiles to life. The 33 Stradale is no exception: it is assembled by hand according to an extremely rigorous protocol.

The process takes place on two parallel lines, each comprising four main stations: assembly, finishing, quality control. Each station is designed to guarantee optimum independence between phases, while allowing millimetric tracking of the vehicle.

It all starts with the "body in white", a pre-assembled aluminum chassis, scanned to perfectly match the mechanical, electronic and structural components. Next comes the integration of the cataphoretically-treated front and rear subframes, which form an H-shaped architecture welded to the carbon monocoque.

The first body component fitted is the carbon-fiber roof, with an internal aluminum structure: a structural reference point that guarantees perfect alignment of subsequent panels. The sides, hoods and doors, all in carbon, are then fitted using special templates, before being manually adjusted by Touring's master craftsmen. Nothing is left to chance: clearances, alignments and fixings are checked and retouched by hand.

Once the framework is complete, the car is sent to Arese to receive its paintwork, applied by hand in three coats: epoxy primer, adhesion primer and finish. Each panel is then polished, checked and reassembled with the finishing elements: glass, lights, grilles, gaskets, etc.

The interior is just as well cared for. Modules are pre-assembled in parallel, then meticulously integrated. At the end of the process, the car goes through the "final delibera": a validation by Touring and then by Alfa Romeo, which examines design, function and dynamic behavior. Only then can it be delivered to its owner.

Bottas won over by experience

Valtteri Bottas, former F1 driver and 33 Stradale customerHe himself tested the car in Balocco. "The feeling is immediate. The experience is close to perfection: responsive, intuitive, with a sound... inimitable. It's a true Alfa Romeo." A strong judgment, coming from a performance expert.

The first copy was delivered on December 17, 2024exactly 58 years after Franco Scaglione was commissioned to design the original 33. A highly symbolic coincidence, bringing the past and future full circle.