Having a Lamborghini is an unattainable fantasy for most enthusiasts. And yet, in a Colorado garden, one man has proved that with patience, technical skill and a healthy dose of passion, this dream can take shape... layer by layer, in 3D printing.

An idea born... from a video game!

The story begins in an almost ordinary way. A father and son are playing Forza on Xbox. On the screen, a Lamborghini Aventador. Fascinated by its lines, the boy asks a simple, almost naive question: "Dad, could we build one?" For many, the discussion would have ended there. But not for Sterling Backus. An engineer with a passion for mechanics, a specialist in laser technology and a track record for complex projects, he doesn't see the question as a joke. He sees it as a challenge.

Four years of work... in a garden

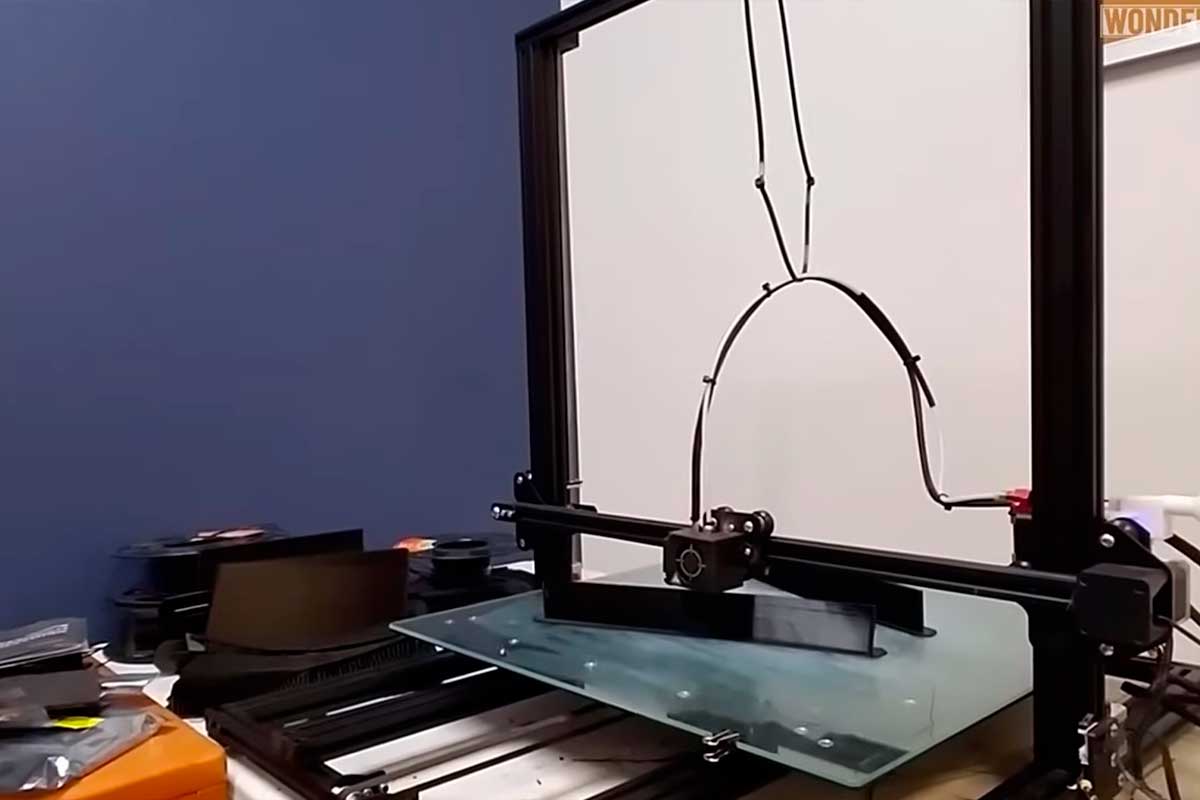

The project starts in 2018. No industrial workshop, no excessive resources. Just a garden, several consumer 3D printers, and a budget set at around $20,000, or just over 17,000 euros. Sterling and his son begin by downloading a 1:10 scale digital model of the Aventador. The file is then enlarged, reworked and cut into hundreds of parts that can be processed by home 3D printers. Each part is printed separately, sometimes over several days at a time. Some parts, such as the front air intakes, require more than 50 hours of continuous printing. In total, almost 1,000 parts are printed, for around 6,000 hours of machine operation. A painstaking task, spread over four whole years.

A supercar... almost entirely printed

Contrary to what you might think, the result is anything but a rough DIY job. From a distance, the car deceives the eye. The proportions are just right, the look immediately recognizable. So much so, in fact, that a simple glance is not enough to realize that this is not an official model. Of course, not everything is printed. Some parts are bought second-hand, salvaged from scrap yards or even donated. For example, the steering wheel, dashboard components, headlights... And above all, the engine.

Under the Lamborghini-inspired bodywork, no naturally-aspirated V12. Sterling Backus opts for an engine: a 5.7-liter LS1 V8, taken from a Chevrolet Corvette C5. Combined with a six-speed manual gearbox from a Porsche 911 and two turbochargers, it develops between 550 and 600 hp.

The legal question quickly arises. Is copying a Lamborghini legal? Sterling anticipated the problem. Each panel is modified, reworked and reinterpreted. The car is a one-off, not for sale, with no official badge.

"Why not buy a real one?"

It's the question that comes up most often in commentaries and at exhibitions. Why spend four years building a replica, when you could just save up and buy a real supercar? Sterling Backus answers without hesitation. For him, the question is almost incomprehensible. Creating a car with your own hands gives you a feeling that buying can never replace. He explains that the simple act of designing, assembling, problem-solving and seeing the car drive is, in his words, "the best feeling in the world". Far greater than signing a cheque or receiving the keys to a new model. It's the culmination of years of work, doubts, mistakes and successes shared with his son.

An offer of $100,000... refused

With an estimated total cost of $20,000, the investment/result ratio is spectacular (not to mention the time spent). All the more so as the car is rapidly attracting attention at motor shows and events. So much so that an offer of $100,000 was made. A categorical refusal. For Sterling Backus, this car is not for sale. It's a family adventure, an educational project, a demonstration of what passion and perseverance can achieve. Today, the 3D-printed Lamborghini is on the road, exhibited at trade shows, and also serves as an educational tool. Sterling speaks at schools about science, engineering and creativity. His message is simple: technology is no longer the preserve of industrial giants. Well done, sir! Watch the fascinating video below.

Bravo, you really have to be motivated and determined to design this kind of vehicle.

I also admire